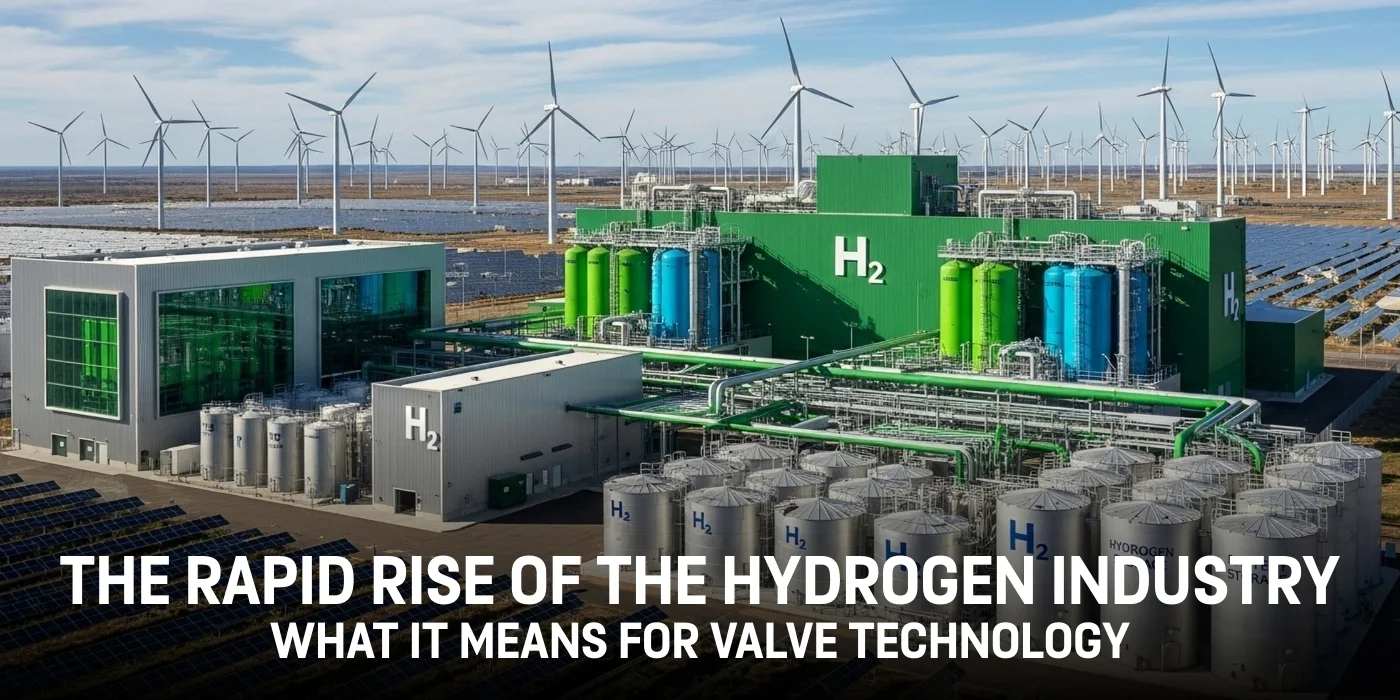

The Rapid Rise of the Hydrogen Industry and What It Means for Valve Technology

Hydrogen is rapidly shifting from a future concept to a central pillar of global energy and industrial strategy. With governments investing heavily in hydrogen production, transport and clean-fuel infrastructure, the entire value chain is expanding at speed — from gigawatt-scale electrolysers to high-pressure refuelling stations. And as the sector grows, so does the need for components that can safely handle hydrogen’s unique challenges, with valves sitting right at the heart of that requirement.

What Is Hydrogen?

Hydrogen (H2) is the lightest, smallest, and most abundant element, and its behaviour is unlike typical industrial gases. Its tiny molecules move quickly, permeate materials easily, and leak through clearances most gases can’t. Hydrogen burns cleanly, has a high energy content per kilogram, and can be produced using low-carbon or renewable pathways — especially through electrolysis powered by wind, solar or nuclear energy.

These properties make hydrogen ideal for clean energy applications, but they also make it demanding to work with. Any component used in hydrogen service must be built with precision, compatibility and long-term durability in mind.

Why the Hydrogen Industry Is Growing

The global shift toward decarbonisation is the biggest driver of hydrogen’s rise. Many industries simply cannot electrify, including steelmaking, chemicals, heavy transport, marine, aviation, and high-temperature manufacturing. Hydrogen offers a viable low-carbon alternative.

It also provides large-scale energy storage capabilities — storing excess renewable electricity as hydrogen for later use. Combined with government incentives, mobility development, new pipeline plans, and expanding industrial applications, hydrogen has become one of the fastest-growing segments of the energy sector.

But as the industry scales, engineering demands increase dramatically — and that brings valves into focus.

Why Only Certain Valves Are Suitable for Hydrogen

Hydrogen is unforgiving. Many standard valves used for air, nitrogen or natural gas aren’t suitable for hydrogen because:

-

The molecule is extremely small — making leakage far more likely.

-

Hydrogen permeates and weakens certain metals, causing embrittlement.

-

Soft seats and standard seals can absorb or diffuse hydrogen, reducing performance.

-

High purity requirements demand materials that won’t contaminate fuel-cell-grade hydrogen.

-

High pressures in refuelling, storage and transport systems exceed typical industrial ratings.

For these reasons, hydrogen systems require purpose-built valves with engineered sealing, compatible materials, and tight tolerances.

The H2SEAL JC Hydrogen Valve

The H2SEAL JC Hydrogen Valve is designed specifically to handle hydrogen’s unique demands. Key features include:

Hydrogen-Optimised Sealing

Advanced seat and seal designs minimise micro-leakage and maintain reliable shutoff even under pressure cycling.

Hydrogen-Compatible Materials

The valve uses alloys that resist embrittlement and maintain structural integrity over long-term hydrogen exposure.

High-Pressure Capability

Suitable for 350–700 bar environments common in hydrogen distribution and refuelling infrastructure.

Purity Protection

Clean construction and hydrogen-safe materials help maintain the high purity levels required in fuel-cell systems.

Precision Engineering

Tight machining tolerances and polished sealing surfaces ensure controlled, low-emission performance.

The H2SEAL JC Valve represents the type of specialised technology that will support the next wave of hydrogen growth.

Where Hydrogen Valves Are Used

Hydrogen-ready valves appear across the full hydrogen value chain:

-

Production – electrolysers, reformers, and compressors

-

Storage – high-pressure vessels and liquid hydrogen tanks

-

Transport – pipelines, tube trailers, and distribution hubs

-

Refuelling – 350 bar and 700 bar mobility systems

-

Industrial Use – power, refining, chemical plants, fuel-cell systems

Wherever hydrogen flows, valves provide essential control, isolation and safety.

Conclusion

The hydrogen industry is expanding quickly, and its success depends on reliable systems designed for the unique properties of H2. Valves are one of the most critical components in this chain — responsible for containing, controlling and safeguarding hydrogen across production, storage, transport and end-use applications.

Hydrogen-ready solutions such as the H2SEAL JC Hydrogen Valve deliver the performance, purity and safety the sector demands, making them a key part of the infrastructure powering the hydrogen transition.

Wherever hydrogen flows, valves provide essential control, isolation and safety.