Chest Valves Explained: The Control Centres of Complex Flow Systems

What Is a Valve Chest?

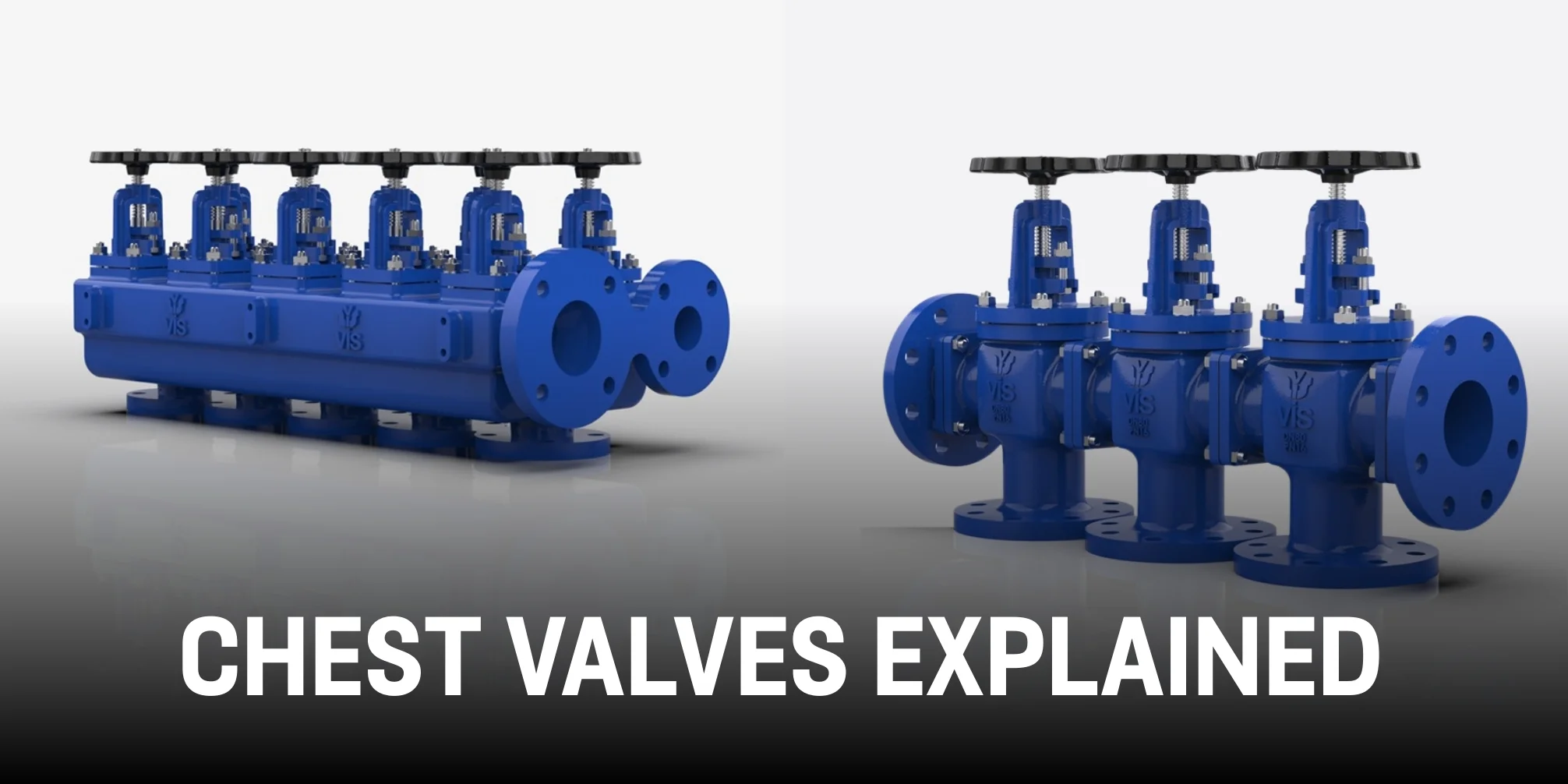

Chest valves—more accurately known as valve chests—are compact assemblies that house multiple valves within a single body. Instead of relying on scattered individual valves and sprawling pipework, a valve chest brings several flow paths together into one organised unit.

This allows operators to manage, isolate, redirect, or protect multiple circuits from a central point, simplifying system design and improving operational clarity.

Where Valve Chests Are Used

Valve chests are most commonly found in marine environments. Engine rooms on ships rely on them to control seawater intake, bilge systems, ballast tanks, cooling circuits, and fuel transfer lines. In these settings, space is limited and reliability is critical. A valve chest allows crews to isolate or redirect flow instantly—whether during routine operation or in an emergency.

Beyond maritime use, valve chests are widely employed in industrial plants, steam systems, hydraulic machinery, and specialist equipment. Anywhere multiple fluid lines converge, a valve chest offers a cleaner, safer, and more efficient solution.

Power stations use them in steam and condensate networks, manufacturers integrate them into high-pressure process lines, and bespoke machinery often depends on custom valve chests to manage complex flow paths within a compact footprint.

Types of Valve Chests

Designs vary depending on the application. Modular or “cell type” valve chests are built from individual valve units assembled together, providing flexibility for two, three, four, or more valves in one assembly. Monoblock valve chests are cast as a single solid body, offering exceptional rigidity and a very compact form.

Customised valve chests go even further, built to exact specifications for unusual layouts, retrofits, or specialist systems where standard solutions simply won’t fit.

The Role of SDNR Valves

Many valve chests incorporate SDNR valves—Screw Down Non-Return.

These allow flow in one direction while preventing backflow, with the added ability to fully shut off the line.

This is critical in systems such as bilge suction or fuel transfer, where reverse flow could cause serious operational or safety issues.

Manual and Automated Operation

Modern valve chests are no longer limited to manual handwheels.

They can be fitted with pneumatic or electric actuators and integrated into wider control systems.

In agricultural machinery, ISOBUS-enabled valve chests allow operators to manage multiple spray or feed lines electronically from a cab. In industrial plants, remote actuation enables precise, repeatable control and reduces the need for manual intervention in hazardous areas.

Why Valve Chests Matter

What makes valve chests so valuable is not just what they do, but how they simplify everything around them.

They reduce pipework, cut down on potential leak points, improve system clarity, and centralise control. Maintenance becomes easier. Training becomes simpler. Emergency response becomes faster.

In complex fluid systems, chaos is expensive and dangerous. Valve chests replace that chaos with structure. They turn a web of pipes into an organised control hub, ensuring that flow is managed safely, efficiently, and with absolute clarity.

Whether in the heart of a ship or the core of an industrial plant, valve chests remain one of the most practical and powerful tools in fluid control engineering.